I’ve got a problem on my hands. The leather industry’s carbon footprint is huge. Each square meter of cow leather creates 110 kg of CO2e. This is a big issue.

Every year, over a billion animal hides are tanned. This causes serious problems for the environment and animal welfare. But, there’s hope. We can make leather production better.

We can do this by using eco-friendly tanning processes. By focusing on reducing carbon footprint, we can change the industry for the better.

Key Takeaways

- Leather production significantly impacts the environment, with each square meter generating 110 kg of CO2e

- Over a billion animal hides are tanned annually, raising environmental and animal welfare concerns

- Sustainable leather production is achievable through eco-friendly tanning processes

- Reducing carbon footprint in leather manufacturing is crucial for industry transformation

- Implementing innovative technologies can lead to more sustainable leather production practices

Introduction to Leather Manufacturing and Carbon Footprint

I’ve been looking into the leather industry’s environmental impact. The findings are shocking. The global leather market struggles with sustainable production and cutting its carbon footprint. Let’s explore this complex issue further.

The global leather market and its environmental impact

Environmental worries have moved leather production to places like Latin America, India, and China. This change has caused pollution problems for farming and clean water. The industry is now moving towards a circular economy. It aims for sustainable resource use and tracking every step of production.

Understanding carbon footprint in the context of leather production

Carbon Footprint in Leather Industry is key to making leather sustainable. Life Cycle Assessment (LCA) helps measure leather’s environmental impact. LCA has four main steps: setting goals, analyzing inventory, assessing impacts, and interpreting results.

| Aspect | Traditional Leather | Vegan Leather (Carter Industrial Company) |

|---|---|---|

| CO2 Emissions | High | Saves up to 17 tonnes of CO2 per tonne produced |

| Water Consumption | High | Saves up to 53 tonnes of water per tonne produced |

| Processing Methods | Chemical-intensive | Eco-friendly |

| Raw Materials | Animal hides | Laminated safety glasses (upcycled) |

The leather industry is moving towards being more sustainable. But, there are still big challenges. By January 2023, only 39% of companies had set targets for reducing emissions. Only 18% were on track to meet these targets. This shows we need to keep working on making leather production more sustainable and reducing its carbon footprint.

The Environmental Challenges of Traditional Leather Production

I’ve been looking into the environmental effects of leather making. The results are shocking. Traditional leather making is really bad for our planet. Here are some key stats that show we need to change how we make leather.

The leather industry uses a lot of resources. For every kilogram of leather, up to 2.5kg of chemicals and 250 liters of water are used. This process also creates up to 6.1kg of waste, harming our environment.

Livestock farming, key in leather making, causes 14.5% of global greenhouse gas emissions. This shows we need better ways to make leather.

| Resource | Traditional Leather | Plant-Based Leather |

|---|---|---|

| Water Usage | 17,000 liters/kg | 190% less |

| Chemical Use | High (toxic) | Minimal |

| Carbon Footprint | High | Lower, carbon sequestration |

Leather making’s environmental harm goes beyond just using resources. The tanning process uses harmful chemicals like chromium. These chemicals pollute our waterways, harming both our health and the environment.

Looking to the future, plant-based leathers are a good option. They use less water and chemicals, and they help protect our planet by needing less land and using leftover crops.

Reducing Carbon Footprint in Leather Manufacturing

I’ve found some cool facts about making leather better for the planet. The leather world has big environmental problems. But, new ways of making leather are helping it become greener.

Key Areas for Carbon Reduction

There are key spots to cut down carbon in leather making. These include getting materials in a green way, using eco-friendly tanning, saving energy, and managing waste well. By working on these, the leather industry can make a big difference.

Innovative Technologies for Sustainable Production

New tech is changing leather making for the better. Chrome-free and veg tanning are becoming more common. They use natural stuff and cut down on bad chemicals.

Water-based and solvent-free finishes also help the planet. Let’s look at how different leathers compare in carbon emissions:

| Leather Type | CO2 Emissions (kg/m²) |

|---|---|

| Natural Leather | 17.0 |

| Synthetic Leather | 15.8 |

| Bio-based Leather (estimated) | 12.5 |

Companies like Modern Meadow are making bio-based materials. These could change the game. They might cut carbon emissions a lot while keeping leather strong and good-looking.

Sustainable Sourcing of Raw Materials

I’ve found that using sustainable leather is a big step in making leather products better for the planet. The leather industry has big environmental problems. Livestock farming is a big part of these issues, causing about 14.5% of greenhouse gas emissions. Now, we’re moving towards using eco-friendly materials and new ways to get them.

Plant-based leather alternatives are becoming more popular. They’re made from things like mushrooms, pineapple, corn, and green tea. These options could help make leather production less harmful to the environment.

| Sustainability Goal | Achievement |

|---|---|

| Product Catalog Sustainability | 50% recycled, carbon-neutral, or renewable materials by 2030 |

| Weight Reduction | Synthetics up to 43% lighter than competitors |

| Carbon Neutrality | Alcantara® certified carbon neutral since 2009 |

| Chemical Reduction | 46% decrease in leather processing chemicals |

| Water Conservation | 91% reduction in fresh water usage |

These steps towards sustainable leather are not just good for the planet. They also open up new chances. For example, some companies are working on social projects. They give away leftover leather to help people find jobs and improve the economy.

The path to fully sustainable leather is still long, but we’re making good progress. As buyers, we can help by picking products made from green materials. We should also support companies that care about the environment.

Eco-Friendly Tanning Processes

I’ve noticed a big change in leather making. The old ways were bad for the planet. Now, we’re using methods that are kinder to our environment.

Chrome-free and Vegetable Tanning Methods

Chrome-free tanning is becoming more popular. It doesn’t use harmful chemicals. Vegetable tanning uses plant tannins, which is better for the planet.

Water-based and Solvent-free Finishing Techniques

Water-based finishes are a big improvement. They use less harmful chemicals. Solvent-free methods also help reduce pollution in leather making.

| Tanning Method | Environmental Impact | Durability |

|---|---|---|

| Chrome Tanning | High | High |

| Vegetable Tanning | Low | Medium |

| Chrome-free Tanning | Medium | High |

These new tanning methods are changing the leather world. They’re leading to more green and innovative ways of making leather. It’s great to see the industry moving towards a more sustainable future.

Energy Efficiency in Leather Production

I’ve found that making leather uses a lot of energy. Most of this energy comes from fossil fuels. This makes a lot of CO2 emissions in the leather world.

Being energy-efficient in tanneries is very important. A study showed that energy use for making leather can vary a lot. It can be from 29 to 53.4 MJ/m² in different tanneries. One tannery even used 160 MJ/m² because of special technology.

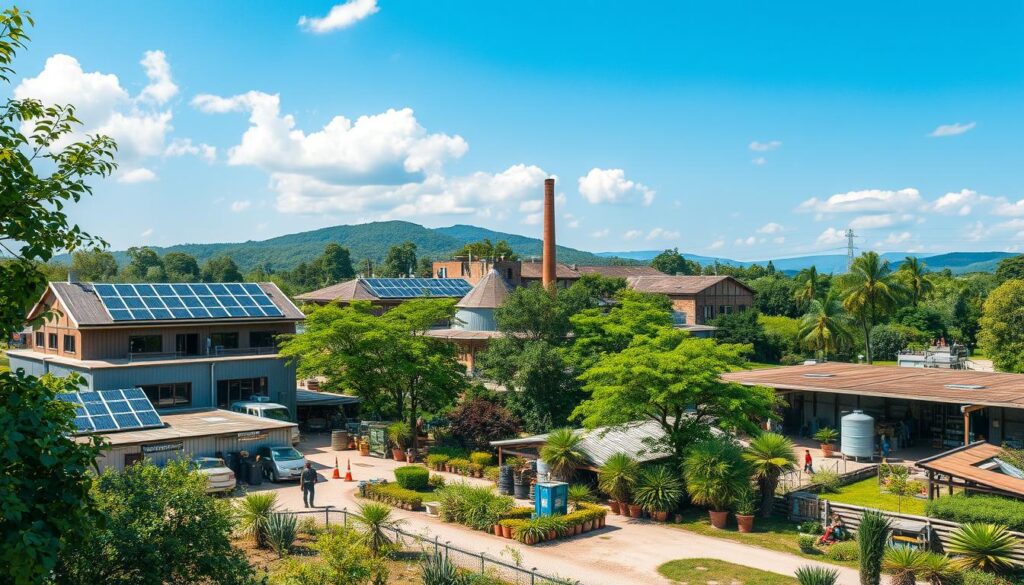

Using renewable energy in making leather can help a lot. Solar energy systems, like photovoltaic thermal hybrids, are good for tanneries. They help use less fossil fuel and cut down on carbon emissions.

I found some good tips for saving energy in tanneries:

- Optimizing electrical equipment like motors

- Using voltage stabilizers

- Implementing cogeneration and tri-generation systems

- Improving heat recovery processes

- Replacing traditional bulbs with LEDs

- Maintaining heat exchangers

By following these tips, tanneries can save energy and money. They can also reduce CO2 emissions. It’s clear that focusing on energy efficiency and using renewable energy are key for a greener leather industry.

Waste Management and Circular Economy in Leather Manufacturing

The leather industry is focusing more on waste management. This is key to solving environmental problems and making a greener future. Let’s explore some important points about this topic.

Reducing Solid Waste and Wastewater

The leather industry makes a lot of waste. For every 1 Mg of raw hides, only 200 kg is useful. The rest is waste, like up to 150 Mg of shaving waste and 4 Mg of trimming waste each month. It’s a big challenge.

Water use is also a big issue. Making leather can use 15,000-120,000 m3 of water for 1 Mg of raw material. This creates 15-50 Mg of wastewater. Some companies are using better wastewater treatment to lessen this problem.

Upcycling and Recycling Leather Waste

Circular economy practices in leather manufacturing are exciting. Recycling 300 million hides from meat and dairy saves 7.5 million tons of waste yearly. This also cuts 2.7 million tons of greenhouse gas emissions.

Leather goods can be fixed and recycled. They break down in 25 to 45 years in nature, or 10 to 15 years in landfills. This helps with sustainability efforts.

| Waste Type | Amount | Potential Circular Economy Solution |

|---|---|---|

| Shaving Waste | Up to 150 Mg/month | Upcycle into leather board |

| Trimming Waste | Up to 4 Mg/month | Recycle into small leather goods |

| Wastewater | 15-50 Mg/1 Mg raw material | Advanced treatment for water reuse |

By using circular economy ideas, the leather industry can cut its environmental impact a lot. It’s a big step towards a greener future in leather making.

Green Supply Chain Management for Leather Industry

I’ve noticed a big change in the leather industry. They’re moving towards green supply chain management. This is key to lowering the carbon footprint of leather making.

Leather making’s carbon emissions vary a lot. They can be from 35 to 320 kg/m², with an average of about 110 kg/m². This shows there’s a lot of room for improvement.

Traceability is a big part of green supply chain in leather making. Some can tell where the rawhides come from. But, they often don’t know about the animals’ origins. This makes it hard to track everything.

- Groups like the Sustainable Leather Foundation (SLF) are helping. They work on making traceability better.

- The “Leather Traceability Cluster” is also working on this. They aim to make the leather supply chain more open.

It’s important to use sustainable practices in the supply chain. This means better transport, less chemical use, and working with suppliers to lower emissions. By doing this, we can make the leather supply chain more green and lessen its harm to the environment.

Carbon Offsetting Strategies for Leather Manufacturers

I’ve noticed a big push for Carbon Offsetting in the leather industry. This is because they want to lessen their harm to the environment. With the leather market expected to hit $629.95 billion by 2025, it’s key for makers to go green.

Now, Sustainable Leather Manufacturing includes carbon offsetting. This helps along with cutting down direct emissions. For instance, DANI, a top leather company, has a detailed plan:

- Offsetting direct (scope 1) and indirect (scope 2) emissions

- Preparing an inventory of impacts using ISO 14064-1 standards

- Verifying compliance through independent certification

- Participating in certified projects in developing countries

DANI says they’re carbon neutral, beating the 2050 European goal. This shows the industry what’s possible. Other leather makers can also go green by planting trees or backing clean energy.

Leather from cow skin makes about 17.0 kg of CO2e per square meter. But, when we add farm emissions, it’s 110.0 kg CO2e/m2. These numbers show how vital carbon offsetting is for making leather better.

The leather industry faces competition from new materials. But, by using carbon offsetting, they can stay ahead and be kinder to the planet.

Life Cycle Assessment of Leather Products

I’ve been looking into Life Cycle Assessment (LCA) of leather products. It’s really interesting. LCA helps us see how leather goods affect the environment from start to finish. In the last six years, 30 out of 39 studies on this topic were published.

Cradle-to-grave analysis of leather goods

The LCA process has four main steps. These are defining goals and scope, analyzing inventory, assessing impacts, and interpreting results. This detailed method helps us understand and improve the leather industry’s environmental effects.

It looks at things like climate change, ozone depletion, and how harmful substances are to humans. It also considers how much dust is released into the air.

Comparing carbon footprints of different leather types

When we compare carbon footprints, bovine leather has the biggest impact. It uses a lot of carbon, is toxic, and uses a lot of water. PU leather is another option, but it also has environmental costs because it’s made from non-renewable materials.

But, mycelium leather is the most eco-friendly. It has the lowest scores in all environmental areas.

| Leather Type | Carbon Footprint | Sustainability Ranking |

|---|---|---|

| Bovine Leather | High | 3 |

| PU Leather | Medium | 2 |

| Mycelium Leather | Low | 1 |

The leather industry is working hard to be more sustainable and open about its supply chain. It’s moving towards a circular economy. This means focusing on treating waste, recycling, and thinking about the whole life cycle of leather production.

Alternative Materials: Plant-Based and Vegan Leather Options

I’ve been looking into Plant-Based Leather, and it’s really interesting. These Vegan Leather Alternatives are making a big change. The leather industry is huge, worth $242.85 billion in 2022. But it has a big carbon footprint.

Traditional cow leather makes a lot of CO2e, about 110 kg per square meter. That’s a lot!

Plant-Based Leather is better for the environment. It’s made from things like mushrooms, pineapples, and cacti. These materials only make 0.8 to 8.8 kg CO2e per square meter. That’s a huge difference!

Even synthetic vegan leather, at 7 to 15.8 kg CO2e/m2, is better than animal leather.

Car companies are starting to use Plant-Based Leather. Mercedes Benz and Bentley are doing it to cut down emissions. It’s not just about being green, though.

These materials are pretty cool. Take Piñatex, made from pineapple leaves. It uses a water-based coating and even includes some biodegradable plastic.

| Material | Source | Environmental Impact |

|---|---|---|

| Desserto | Cactus | Uses local rainwater, avoids harmful chemicals |

| Malai | Coconut waste | Lasts 4-8 years, uses agricultural waste |

| Apple Skin | Apple waste | Uses discarded apple parts |

These Vegan Leather Alternatives aren’t perfect. Some still use plastics, which can be a problem. But they’re a step in the right direction.

As we look for ways to reduce our impact on the planet, Plant-Based Leather offers a promising solution.

Consumer Awareness and Demand for Sustainable Leather

I’ve seen a big change in how people buy leather products. This is because more people know about the bad things in the leather world. So, companies are now making changes to what they sell.

The demand for green leather is changing the market. People want things that match their values. This makes companies look for better ways to make leather.

Because of this awareness, new things are happening. For example, vegan leather is getting more popular. People want products that are kind to animals and good for the planet.

| Material | Advantages | Market Growth |

|---|---|---|

| Bio-based Leather | Eco-friendly, Innovative | 8.2% CAGR (2024-2034) |

| Vegan Leather | Cost-effective, Cruelty-free | Significant expected growth |

| Traditional Leather | Durability, Luxury appeal | Stable with sustainability focus |

The fashion and car worlds are also changing. They’re using plant-based leather to help the planet. This shows a big shift in what people want and value.

Regulatory Framework and Industry Standards for Sustainable Leather

I’ve seen a big change in the leather industry. Now, there are strict rules for being green. This is because of what people want and global efforts.

European Standard EN 16887:2017

The European Standard EN 16887:2017 is a big deal. It sets rules for how to measure leather’s carbon footprint. It starts at the slaughterhouse and ends at the tannery exit.

This standard has made tanneries improve a lot. Now, they use modern, efficient ways to make leather. These ways often go beyond what was required before.

Global Initiatives for Sustainable Leather Production

There are big efforts worldwide to change the leather industry. The Zero Discharge of Hazardous Chemicals (ZDHC) program has over 100 brands and suppliers on board. It makes sure no harmful chemicals are used in making leather.

The Leather Working Group also does important work. They check if raw materials can be traced back to their source.

Now, there’s a big focus on using water and energy wisely in leather making. Water is key for tanning, dyeing, and cleaning. The industry is working on new ways to use less water and energy.

| Sustainability Aspect | Industry Progress |

|---|---|

| Waste Reduction | 7.3 million tonnes saved from landfill annually |

| Traceability | LWG audits tracing raw materials to slaughterhouses |

| Chemical Management | ZDHC program enforcing hazardous chemical elimination |

| Energy Efficiency | Focus on reducing electrical and thermal energy use |

These efforts are making the leather industry better for the planet. The rules keep getting stricter. This pushes the industry to find new, cleaner ways to make leather.

Case Studies: Successful Carbon Reduction in Leather Manufacturing

I’ve looked at many Carbon Reduction Case Studies. They show how Sustainable Leather Manufacturing can help the environment. These examples are real and show progress.

The European Commission started a project in 2013. It looked at the environmental impact of leather products. In 2018, the EU approved rules for measuring leather’s carbon impact. This was a big step forward.

Another study found that processing materials cause 29% of emissions in shoe making. The making phase is responsible for 68% of carbon footprint. This shows we need to focus on these areas to cut carbon.

Now, let’s see some examples of reducing carbon in shoe making:

| Component | Carbon Footprint (%) | Reduction Strategy |

|---|---|---|

| Upper Leather | 35.8 | Eco-friendly tanning processes |

| Sole | 20.4 | Recycled materials |

| Manufacturing | 28.5 | Energy-efficient equipment |

| Packaging | 10.1 | Biodegradable materials |

| Transportation | 5.2 | Optimized logistics |

These examples show big carbon cuts are possible. The fashion world is moving towards better materials. More people are also becoming aware of the need for change.

Conclusion

I’ve looked into how to cut down on carbon footprint in leather making. The future of green leather depends on mixing old ways with new tech. The leather industry has a big problem with carbon, with about 15,190 kgCO2 for every 100 m2 of leather.

Getting raw materials is the biggest source of greenhouse gases in leather making. This shows we need to find better ways to get materials. The tannery’s carbon footprint is around 2.2 kgCO2 for every kilo of leather. This shows we must use greener tanning methods.

Life Cycle Assessment (LCA) is key for checking environmental effects. The Product Carbon Footprint (PCF) and Carbon Footprint Product Category Rules (CF-PCR) help the leather industry be more green. As more people want eco-friendly products, the future of green leather looks bright. This is thanks to new tech and stricter rules.