I’ve always been fascinated by how leather was made in the past. It’s an art that started in the Stone Age. Our ancestors figured out how to make animal hides last a long time. That’s pretty cool, right?

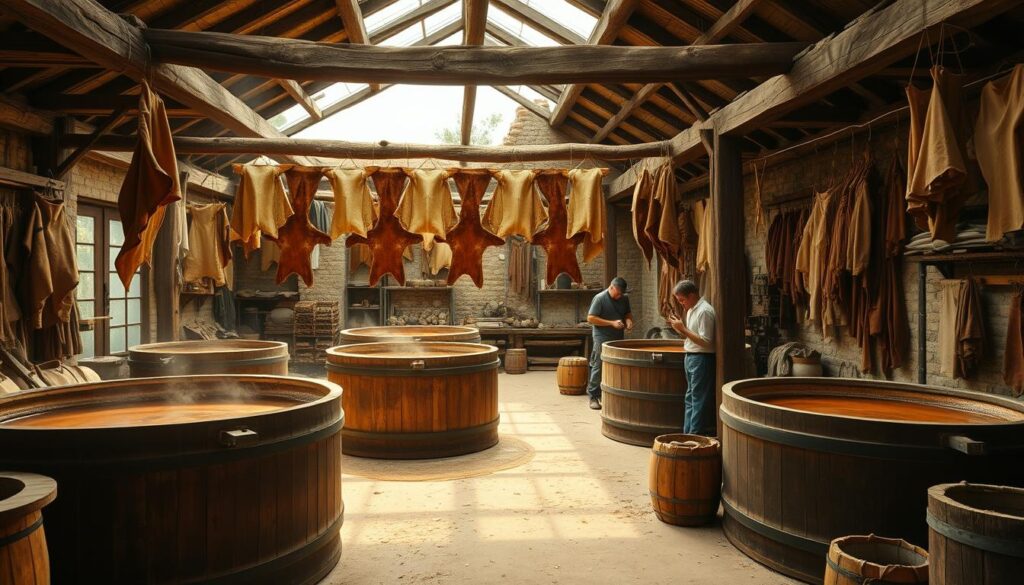

Artisanal leather crafting is more than a job. It’s a skill passed down through generations. These craftsmen spend years perfecting their techniques. They’re not just making leather; they’re keeping history alive.

What’s really interesting is how sustainable leather manufacturing has become. Today, some tanneries use plant-based materials instead of harsh chemicals. It’s a nod to old-school methods while being kind to our planet.

Key Takeaways

- Leather tanning dates back to the Stone Age

- Artisanal crafting preserves historical techniques

- Sustainable methods are gaining popularity

- Vegetable tanning uses natural plant materials

- Traditional techniques require significant skill and time

The Ancient Art of Leather Making

Leather making is as old as humans. I find it amazing how our ancestors made animal hides into strong materials. Leather’s story shows our creativity and ability to adapt.

Origins of Leather Tanning

Leather tanning started long ago. The ancient Egyptians and Mesopotamians began using plants to tan leather around 3000 BCE. They used Acacia nilotica bark, showing early innovation in leather making.

Importance in Human History

Leather was key in ancient times. In Rome, leather was made soon after it was founded in the 8th century BCE. In the Middle Ages, leather was used for many things in Europe, like belts and chairs.

Evolution of Tanning Techniques

Leather tanning techniques changed over time. Early methods were simple, but as cultures grew, so did the techniques. In Fez and Marrakesh, artisans used natural colors for dyeing. The Industrial Revolution made leather making more efficient and diverse.

Now, 80-90% of leather making uses chrome methods. But, there’s a push to use traditional methods again. This mix of old and new keeps leather important in our world.

Why Tan Leather?

I’ve always been fascinated by the art of leather preservation. Tanning leather is key to making raw animal hides last long. Without it, leather would quickly fall apart, not good for daily use.

The main goal of tanning is to keep the collagen in the hide stable. This stops it from decaying and makes it water and heat proof. It’s cool to know that untanned hide shrinks in water at just 62°C. But chrome-tanned leather can handle up to 100°C!

Eco-friendly leather processing is getting more attention lately. Old methods like vegetable tanning use plants to make leather more green. This method makes beautiful brown leather that gets better with age.

Here are some key reasons why we tan leather:

- Prevents decay

- Increases water resistance

- Improves heat resistance

- Preserves flexibility

- Enables various product applications

Understanding leather tanning helps us see the skill in leather goods we use daily. From shoes and jackets to furniture and accessories, tanned leather is durable and beautiful. It’s far better than raw hides.

The Basics of the Tanning Process

The leather tanning process is very old. It turns raw animal hides into strong, flexible materials. This craft has changed a lot over thousands of years, starting in the Stone Age around 8,000 BCE.

Preparation of Raw Hides

The first step is to prepare the raw hides. They are cleaned, fleshed, and trimmed. This removes extra fat and flesh. It’s key for making high-quality leather.

Beam House Operations

Then, the hides go through beam house operations. They are soaked, limed, and dehaired. The hide is split to get the right thickness. This gets the hide ready for tanning.

Tanning and Finishing

The main part is treating the hide with tanning agents. Chrome-tanning is common today, but old methods like vegetable tanning are still used. Vegetable tanning uses plant tannins from mimosa or chestnut, starting 3,000 BCE.

After tanning, the leather gets finishing treatments. This includes dyeing, oiling, and applying protective coatings. Some leathers get special treatments for unique looks. For example, Absolute and Parliament leathers are ironed for a glossy finish.

| Tanning Method | Origin | Characteristics |

|---|---|---|

| Vegetable Tanning | 3,000 BCE, Egypt and Mesopotamia | Eco-friendly, durable |

| Alum Tanning | 800 BCE, Romans | Produces tough and supple leather |

| Chrome Tanning | Modern era | Most prevalent, fast process |

Brain Tanning: A Primitive Technique

I’ve always been fascinated by indigenous tanning techniques. Brain tanning is one of the oldest methods in making leather. It dates back to the Stone Age, around 8000 BCE. This shows how important it has been for thousands of years.

Brain tanning uses fats and oils from the animal’s brain to tan its own hide. It’s been used by indigenous peoples all over the world. This includes the Plains First Nations and Zulus. The process involves several steps:

- Skinning and fleshing

- Soaking

- Graining

- Braining

- Stretching

- Smoking (often)

The leather made from this process is called buckskin or chamois. It was widely used in early North America. Between 1755 and 1773, over 2.6 million pounds of deerskins were shipped to England from Savannah, Georgia. This shows how big the trade in buckskins was.

| Year | Event |

|---|---|

| 8000 BCE | Leather tanning dates back to Stone Age |

| 3500 BCE | Oldest leather shoe discovered |

| 1741 | Tanned deerskin trade thrives in Augusta, Georgia |

| 1775-1783 | General Washington orders buckskin for troops during American Revolution |

Brain-tanned leather is the highest quality for clothes. It was not just used by indigenous communities. Frontiers-people, miners, and even Texas Rangers used buckskin. This shows how good and useful this ancient method is.

Vegetable Tanning: Nature’s Way

I’ve always been fascinated by vegetable tanning. It’s an eco-friendly way to make leather that’s been around for thousands of years. This method uses plant-based tannins to turn raw hides into strong, beautiful leather.

Plant-Based Tanning Agents

Vegetable tanning uses natural tannins from plants. Bark tanning is common, using oak, chestnut, and mimosa bark. Willow bark, manzanita leaves, and artichoke leaves are also used. This variety allows for local sourcing, making it sustainable.

The Vegetable Tanning Process

The vegetable tanning process is slow and careful. It can take up to two months, unlike chrome tanning which takes just a day. First, I make a tanning solution from plant extracts. Then, the hides soak in this solution, letting the tannins work their magic.

Characteristics of Vegetable-Tanned Leather

Vegetable-tanned leather is special. It’s thicker, sturdier, and gets a beautiful patina over time. It may not be as water-resistant as chrome-tanned leather, but its durability and natural look are worth it. Italy is famous for its high-quality leather, especially in vegetable tanning.

Choosing vegetable tanning means picking a sustainable, traditional leather-making method. It honors the environment and the long history of leatherworking.

Mineral Tanning: From Alum to Chrome

I’ve always been fascinated by the evolution of leather tanning. The journey from alum to chromium tanning shows human ingenuity. Ancient civilizations like the Sumerians used leather for practical needs as early as 2500 BCE. They even used copper studs on chariot wheels.

Mineral tanning methods have evolved a lot since then. Alum tanning, known to ancient Egyptians and Romans, made soft, white leather. But it wasn’t until the 19th century that chromium tanning changed the game.

The discovery of chromium tanning was accidental. After 1840, doctors used chromium solutions for gut sutures. Tanners then started using chromium sulfate in leather making.

Today, chromium tanning is the most used method. It’s fast and effective, taking only a day or two. The leather is soft, pliable, and has a blue-gray color before dyeing.

| Tanning Method | Duration | Characteristics |

|---|---|---|

| Chromium Tanning | 1-2 days | Soft, pliable, blue-gray before dyeing |

| Vegetable Tanning | Several weeks | Firm, natural color, ages well |

| Aldehyde Tanning | Few hours | Soft, washable, pale color |

Chromium tanning is efficient but has environmental concerns. This has made people look for sustainable leather making. Aldehyde tanning, a fast process, is now seen as an eco-friendly choice.

The challenge now is to find a balance between efficiency and sustainability. The leather industry is always changing. It seeks new ways to keep traditional craftsmanship while being eco-friendly.

Traditional Leather Tanning Methods

I’ve always been fascinated by traditional leather tanning methods. These old practices have shaped leather production for centuries. They still influence how we make leather today. Let’s look at some amazing indigenous tanning techniques that have lasted through time.

Fat Tanning

Fat tanning is a method I find really interesting. It involves rubbing animal fats into hides. This makes them water-resistant and soft. This technique has been around for centuries and still makes great leather today.

Smoke Tanning

Smoke tanning is another method that caught my eye. It’s often used with brain tanning. Wood smoke is used to preserve and color the leather. This process takes several days but makes a unique, lasting product.

Indigenous Tanning Techniques

Indigenous cultures have their own special tanning methods. For example, some Inuit groups chew seal skins to soften them. These traditional methods make leather types that fit local needs and environments.

| Tanning Method | Duration | Key Feature |

|---|---|---|

| Brain Tanning | Several days | Produces versatile buckskin |

| Bark Tanning | 3-12 months | Uses natural tannins |

| Fat Tanning | Few days | Creates water-resistant leather |

| Smoke Tanning | Several days | Preserves and colors leather |

These traditional methods may take longer, but they have special benefits. For example, brain-tanned leather costs $14 to $16 per square foot. Unlike modern chrome tanning, which can harm waterways, traditional tanning’s waste is often safe for the environment.

The Resurgence of Artisanal Leather Crafting

I’ve seen a big trend in making leather goods by hand. People want unique, high-quality items. They also care about making leather in a way that’s good for the planet.

Using eco-friendly methods to make leather is key. Artisans often tan leather with plants. This helps the environment and fits with the fashion world’s move towards being green.

What makes handmade leather special is its quality and uniqueness. Each piece is made with great care. You can even get things made just for you, so you have something truly special.

| Aspect | Artisanal Leather | Mass-Produced Leather |

|---|---|---|

| Quality | Superior | Variable |

| Customization | Often available | Limited |

| Environmental Impact | Lower | Higher |

| Uniqueness | High | Low |

This trend in making leather goods by hand is great. It makes amazing products and keeps old skills alive. It also helps small businesses grow. It’s a mix of old skills and new care for the planet, just what today’s shoppers want.

Conclusion

I’ve looked into traditional leather tanning methods. They show human creativity and skill. Each method, like brain tanning and vegetable tanning, has its own special qualities.

Chrome tanning is common because it’s fast and efficient. But, people are now interested in making leather in a more sustainable way. Vegetable tanning, which takes longer, makes leather that gets better with age. It’s better for the planet but costs more.

The leather world is changing. Old ways of making leather are coming back. At the same time, there are new efforts to make chrome tanning greener. This mix of old and new might help the leather industry grow while protecting our planet.