Are you lost in the world of leather buying? I’ve been there too. Choosing between direct and indirect sourcing can be tough. It’s not just about the price; it’s about quality, being green, and being fair too.

But don’t worry, I’m here to guide you. In this guide, I’ll explain the main differences between direct and indirect leather sourcing. This will help you make smart choices for your leather needs.

Key Takeaways

- Direct sourcing means buying leather straight from tanneries

- Indirect sourcing uses middlemen in the leather chain

- Direct sourcing usually means better quality control

- Indirect sourcing offers more choices and flexibility

- Being green is key in both ways of sourcing leather

- Being fair is also very important in buying leather

Understanding Procurement in the Leather Industry

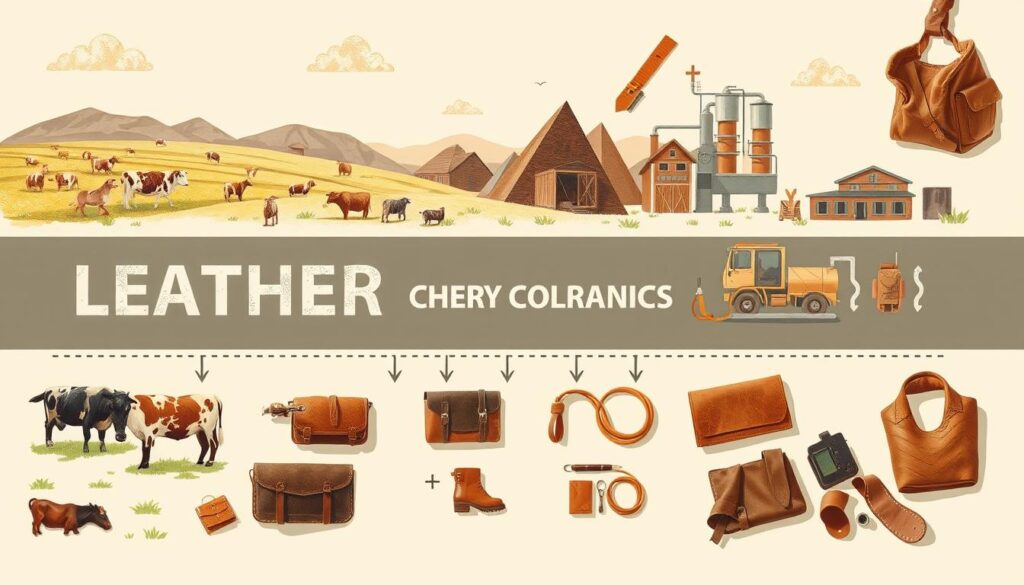

Leather procurement is a complex process. It involves getting the materials and services needed for leather products. Let’s explore what this means and why it’s crucial.

Definition of Procurement

Leather procurement is about buying raw materials for leather making. This includes hides, chemicals, and other supplies. It’s vital for the leather industry’s smooth operation.

Importance of Procurement in Leather Business

Procurement is key in the leather business. It impacts product quality, costs, and profits. Good procurement ensures a steady supply of materials, meeting customer needs and keeping profits up.

Key Factors in Leather Procurement

Several factors are crucial in leather procurement:

- Quality of raw materials

- Supplier relationships

- Cost management

- Responsible procurement practices

- Traceability of materials

Responsible procurement and traceability are now more important. Consumers want to know where their leather comes from. This has led to a focus on sustainable and ethical sourcing.

| Procurement Factor | Impact on Leather Industry |

|---|---|

| Quality of raw materials | Determines final product quality |

| Supplier relationships | Ensures consistent supply |

| Cost management | Affects product pricing and profit margins |

| Responsible procurement | Enhances brand reputation |

| Traceability | Meets consumer demand for transparency |

Direct vs. Indirect Leather Sourcing: An Overview

In the leather supply chain, I’ve noticed two main approaches: direct sourcing and indirect sourcing. Each plays a unique role in the industry’s operations.

Direct sourcing means buying raw materials like hides and tanning agents straight from suppliers. This method gives me more control over product quality. It also helps streamline the supply chain. For example, I can trace 80% of leather back to individual hides using DNA molecules or barcodes.

Indirect sourcing, on the other hand, covers supporting services such as office supplies or marketing. While not directly tied to leather production, these elements keep the business running smoothly.

Understanding these differences is crucial for managing costs and supplier relationships effectively. Let’s look at some key statistics:

| Aspect | Direct Sourcing | Indirect Sourcing |

|---|---|---|

| Primary Focus | Raw materials (hides, tanning agents) | Supporting services (office supplies, marketing) |

| Impact on Product | Direct influence on quality | Indirect support of operations |

| Supply Chain Mapping | 10-year plan to map from finished leather to slaughterhouse | Not typically mapped |

| Traceability Systems | DNA molecules, barcodes, physical stamping | Standard inventory systems |

By balancing direct and indirect sourcing, I can optimize my leather supply chain for both quality and operational efficiency.

Direct Leather Sourcing: A Deep Dive

I’ve found that direct leather sourcing changes the game. It means skipping the middleman and going straight to the source. This method has changed how we get leather, giving us more control over the whole process.

Characteristics of Direct Sourcing

Direct sourcing means I work directly with tanneries and suppliers. This hands-on way lets me watch over every step, from picking raw hides to the final leather. It’s more work, but it leads to better quality and consistency.

Benefits of Direct Leather Sourcing

The benefits are clear. I can build strong relationships with suppliers, which is key. It also lets me control the leather quality better. I can make sure the leather is just right, cutting down on waste and improving quality.

| Benefit | Impact |

|---|---|

| Better Quality Control | 84% of customers prioritize sustainability |

| Cost Efficiency | Reduced errors with integrated WMS |

| Sustainability | 66% of consumers pay more for responsible brands |

Challenges in Direct Sourcing

It’s not easy, though. Managing inventory and keeping up with market changes is hard. But with the right tools, like warehouse management systems, I can handle these challenges. This way, I can enjoy the benefits of direct leather sourcing.

Despite the challenges, direct leather sourcing has big advantages. It’s great for quality, cost, and building strong supplier relationships. It’s making the leather industry better for everyone.

Indirect Leather Sourcing: Exploring the Alternatives

I’ve been looking into indirect leather sourcing. It’s amazing how it changes the leather world. Indirect procurement means buying things that help make leather but aren’t part of it. This includes office supplies, marketing, and managing buildings.

One great thing about indirect sourcing is how flexible it is. We can work with many suppliers. This helps us adjust to market changes. But, it’s not easy. Keeping costs down and making more money is key.

Let’s dive into some important points about indirect sourcing in the leather industry:

- Supply chain management gets more complicated

- Leather industry services often fall under this category

- It needs a different way to deal with suppliers

Good management of indirect sourcing can really help. For example, in 2017, the leather market in America was worth $217.49 billion. By improving indirect procurement, companies can get a bigger piece of this market.

| Aspect | Direct Sourcing | Indirect Sourcing |

|---|---|---|

| Focus | Raw materials (hides, chemicals) | Support services and goods |

| Impact on final product | Direct | Indirect |

| Supplier relationships | Often long-term | More flexible, multiple suppliers |

| Cost management | Easier to track | Requires careful spend management |

By mixing direct and indirect sourcing, leather companies can improve. They can stay ahead in this fast-changing industry.

The Impact of Sourcing Methods on Leather Quality

Sourcing methods greatly affect leather quality. Let’s explore how different methods shape the final product.

Quality Control in Direct Sourcing

In direct sourcing, quality control is tighter. Companies can pick and process materials themselves. This hands-on method usually results in better quality.

Quality Assurance in Indirect Sourcing

Indirect sourcing adds more complexity to quality assurance. It needs strong supplier checks and quality systems. Companies use strict checks to keep standards high, even from a distance.

Comparing Quality Outcomes

Direct and indirect sourcing have different outcomes:

| Aspect | Direct Sourcing | Indirect Sourcing |

|---|---|---|

| Control | High | Moderate |

| Consistency | More consistent | Can vary |

| Traceability | Easier to trace | More challenging |

| Sourcing Impact | Direct influence | Indirect influence |

The impact of sourcing on leather quality is clear. Direct sourcing leads to more consistent results. But, indirect sourcing can also produce high-quality leather with the right steps.

Cost Implications of Direct and Indirect Leather Sourcing

Understanding the costs of direct and indirect leather sourcing is key. It helps in making better choices for buying leather. Let’s look at how these methods affect the leather industry’s finances.

Direct sourcing costs more upfront but can save money in the long run. Buying in bulk and cutting out middlemen saves money over time. Indirect sourcing might cost less at first but can add up to more money later.

To understand which method is more cost-effective, I’ve made a comparison table:

| Factor | Direct Sourcing | Indirect Sourcing |

|---|---|---|

| Initial Investment | Higher | Lower |

| Long-term Savings | Potential for significant savings | Limited savings potential |

| Bulk Purchasing | Available | Limited or unavailable |

| Intermediary Costs | Eliminated | Present |

| Price Volatility | More stable | Subject to market fluctuations |

Costs change based on many things like how much you buy, who you buy from, and the market. It’s crucial to look at all costs to make smart choices in leather buying.

By thinking about these costs and doing a detailed analysis, companies can make their leather buying better. This can help them do better financially in the leather industry.

Sustainability and Ethical Considerations in Leather Sourcing

I’ve seen a growing focus on sustainable leather and ethical leather practices in the industry. As consumers become more environmentally conscious, brands are adapting their sourcing methods to meet these demands.

Sustainable Practices in Direct Sourcing

Direct sourcing allows for better control over the production process. I’ve noticed that companies like Clarks are implementing responsible sourcing policies. They’re working with tanneries that comply with environmental standards set by the Leather Working Group. This approach ensures traceability and promotes sustainable leather production.

Ethical Concerns in Indirect Sourcing

Indirect sourcing can present challenges in maintaining ethical standards. I’ve learned that some brands are addressing this by requiring suppliers to provide detailed information about their sourcing practices. For example, suppliers sourcing from Brazil must demonstrate due diligence in avoiding cattle from deforested areas.

Balancing Sustainability and Profitability

Achieving a balance between sustainability and profitability is crucial. I’ve observed that sustainable products often come with higher price tags due to eco-friendly materials and processes. Yet, consumers are increasingly willing to pay more for ethical leather goods. Brands like Stella McCartney have shown that it’s possible to succeed without using animal leather at all, opting for innovative plant-based alternatives instead.

Responsible sourcing in the leather industry isn’t just about environmental impact. It also involves considering animal welfare and fair labor practices. As the demand for transparency grows, I believe we’ll see more brands adopting comprehensive sustainability strategies that address these ethical concerns while maintaining profitability.

Supply Chain Transparency: Direct vs. Indirect Sourcing

Supply chain transparency in the leather industry is a big deal now. The Fair Labor Association (FLA) has been checking working conditions since 2006. They published a 12-step guide in 2017 and updated it in 2023 to help with traceability.

Direct sourcing gives us a clear view of the supply chain. It’s easier to follow raw materials and production. But indirect sourcing is harder because of many middlemen. The FLA guide has tools like an Action Planning Template and Supplier Visit Form to help with both.

The EU’s new rules on deforestation-free supply chains are changing things. Leather buyers, especially in luxury goods, are at risk. Trase’s analysis shows soy from Paraguay has the highest deforestation risk at 11.6 m² per tonne.

To solve these problems, I think using technology and talking clearly with suppliers is important. It helps meet consumer demands and follow regulations in the leather industry.